INCINERATORS FOR HOSPITAL, INDUSTRIAL AND MUNICIPAL SOLID WASTE

PIROMIX – COMBISYSTEM – PIROSTATIC series furnaces are static incinerators operating with controlled combustion (pyrolysis), studied for the disposal of a big range of mixed waste, such as:

– Hospital;

– Industrial;

– Communities in general.

Their particular concept make them easily solve problems related to the disposal of high l.c.v. waste. Among their many advantages it can be mentioned:

• Easy and fast installation and stat-up.

• Easy running.

• Low fuel consumption and operating costs.

• Low and easy maintenance

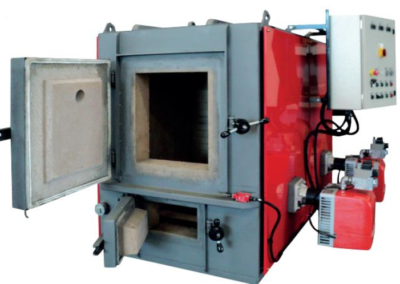

COMBYSISTEM

These furnaces can be used to treat, though pertaining to the medium – high net calorific value waste segment, the widest range of solid waste, from common domestic waste to industrial waste, always in full respect of national and international regulations.

At the same time – the smallest in our production to allow this – they enable rational exploitation of energy from the heat generated by waste, thereby making it possible to link them to a cost-effective heat recovery system for hot water.

Thanks to this characteristic, depending on the method used and the properties of the waste destroyed, the cost of a Combisystem plant with energy recovery is covered in only a few years.

The particular design of these furnaces ensures full compliance with regulations on waste destruction and gas emissions and their operating costs are low.

They are easy to install and easy to use, since they are versatile, they do not require the presence of qualified personnel and benefit from reduced maintenance needs and simple operation.

COMBISYSTEM furnaces do not need to be housed in particular facilities: their size and compact structure enable installation also in areas already built or under the protection of a simple shed.

| COMBISYSTEM | 300 | 500 | 750 | 1000 | 1500 | 2000 | |

| Chamber Volume (m3) | 0,3 | 0,5 | 0,75 | 1 | 1,5 | 2 | |

| Max Load Capacity (kg) | 80 | 120 | 150 | 240 | 270 | 290 | |

| Nominal Burn Rate (kg/hr) | 30/40 | 50/70 | 60/80 | 70/90 | 90/100 | 100/110 | |

| Control Panel | MIC or PLC | ||||||

| Fuel Types | Diesel /Natural Gas | ||||||

| Fire Brick (Alumina) | 0,43 | ||||||

PIROMIX

PIROMIX furnaces are small batch dual combustion incinerators (static combustion chamber associated to afterburner chamber), designed for destruction of solid waste with medium – high calorific values, from urban waste, to hospital and industrial waste. Thus they are suitable for use in small residential areas, hotels, camp sites, small senior citizens homes, clinics, factories, etc.

Even if these are furnaces with the lowest destruction power produced by us – thus suitable for low disposal needs – their operating principle already includes a dual combustion technique. All three models in the PIROMIX series come standard equipped with an afterburner chamber, in addition to the combustion chamber, and a system for constant detection and recording of free oxygen and temperature. They are extremely easy to instal and operate. Thanks to their characteristics and low thermal value, Piromix furnaces do not need to be operated by personnel with particular qualifications or licenses.

These furnaces, among the smallest and most cost-effective of the entire Ciroldi production range, are characterized by gas emissions that generally respect applicable regulations and have low consumption and operating costs.

They are easy to install and to use, since they are versatile, they do not require the presence of qualified personnel and they require very few and easy maintenance operations.

PIROMIX furnaces do not require installation in particular facilities and can also be installed outdoors as long as they are protected by a shed

| PIROMIX | 50 | 90 | 160 | 400 |

| Chamber Volume (m3) | 40 | 90 | 160 | 400 |

| Nominal Burn Rate (kg/hr) | 30 | 50 | 60 | 70 |

| Control Panel | MIC or PLC | |||

| Fuel Types | Diesel /Natural Gas | |||

| Fire Brick (Alumina) | 0,43 | |||

PIROSTATIC

Summary:

This is a static batch furnace with controlled combustion, improperly defined as “pyrolytic”; available in 10 models of different sizes and capacity, concerning size, they are the biggest of this type we manufacture and cover the high-end segment of destruction power characterizing static furnaces.

They are easily able to deal with heat disposal of waste characterized by medium – high calorific values (hospital, industrial, etc.) and low water content.

PIROSTATIC furnaces

This is a static batch furnace with controlled combustion, improperly defined as “pyrolytic”; available in 6 models of different sizes and capacity, concerning size, they are the biggest of this type we manufacture and cover the high-end segment of destruction power characterizing static furnaces.

They are easily able to deal with heat disposal of waste characterized by medium – high calorific values (hospital, industrial, etc.) and low water content.

The two phases of the incineration process enable a considerable reduction in both solid and gas polluting emissions, in addition to their ease of use and high quality performance. Indeed, in many cases the pollutants emitted with gas products are within the limits prescribed by law without accessory reduction systems; additional precautions need to be adopted when stricter limits (EU regulations) and/or waste with particular properties are involved.

The incineration cycle is completely automatic allowing for a significant decrease in the amount of personnel needed compared to traditional batch furnaces. Furthermore, fuel and electricity consumption is much lower.

| PIROSTATIC | 1,5 | 2 | 3 | 4,5 | 6 | 8 | 10 | 12 | 14 | |

| Chamber Volume (m3) | 1,65 | 2,12 | 3,25 | 4,65 | 6,3 | 8,28 | 10,21 | 12,3 | 14,6 | |

| Max Load Capacity (kg) | 270 | 290 | 340 | 460 | 590 | 720 | 880 | 930 | 1080 | |

| Nominal Burn Rate (kg/hr) | 90 | 130 | 150 | 200 | 250 | 290 | 320 | 340 | 400 | |

| Control Panel | MIC or PLC | |||||||||

| Fuel Types | Diesel /Natural Gas | |||||||||

| Fire Brick (Alumina) | 0,43 | |||||||||

INCINERATION PLANTS FOR ORGANIC WASTE, SLAUGHTER HOUSE WASTE AND ANIMAL CARCASSES

Disposal of solid organic waste – which can have several applications, such as those for livestock fields, as well as the meat and foodstuffs industry (animal carcasses and slaughter house waste) – has always had particular attention in the range of high technology plants manufactured by Ciroldi S.p.A. and it is in this sector that our Company gained such wide and extensive experience.

This is how our machines, in addition to respecting environmental regulations, meet specific EU regulations, also the most recent ones, such as Regulation no. 1774/2002/CE and later amendments governing the entire subject of handling animal-based byproducts not for human consumption, such as high and low risk slaughter house waste and animal carcasses.

The range of production includes batch or continuous furnaces, with static or rotating combustion chambers. Destruction capacity ranges from a few dozen kilograms per cycle (RCM) to 550 kg/hour (ROP).

In order to achieve these performance levels, bigger rotating chamber models can generally be equipped with accessory load devices, which enable waste to be fed into the combustion chamber also while running thereby increasing the daily destruction capacity of the plant.

For additional heat disposal needs, RP and Rotomax furnaces, described in the industrial waste section, can be used with particular adjustments.

Depending on specific needs and environmental laws in force, also furnaces for organic waste and carcasses can be fitted with fume treatment systems to lower polluting emissions in order to respect limits set by national and international environmental standards.

Similar to other plants for treating other types of waste, these furnaces can also be associated with heat recovery systems to generate steam or hot water or for heating diathermic oil.

RC/M INCINERATORS

RCM furnaces are horizontal static batch combustion chamber incinerators, specially designed for destruction of small amounts of solid waste and in particular of small and medium size animal carcasses.

These machines, built in three models, are therefore suitable to treat waste from farms, kennels, and small slaughter houses.

RCM furnaces

The extremely simple design of these furnaces, which are already equipped with a thermal afterburner chamber, make them the most cost-effective solution for the problem of animal carcasses, organic waste and specific hazardous materials, and always in respect of applicable national and EU regulations, assuring:

- Simple and quick installation and startup.

- Reduced and easy maintenance operations.

The size of the load hatch and installation of a manual winch, also makes it possible to insert small and medium size animal carcasses without cutting them up.

All three models of the RCM series feature a completely automatic operating cycle. The presence of an afterburner and combustion control devices makes the plants in strict compliance with applicable laws, and also ensures that emissions are without pollutants and generally fall within the limits set by applicable regulations.

| MODEL | |||

| RCM 130 | RCM 350 | RCM 550 | RCM 1000 |

| static | static | static | static |

| “batch” | “batch” | “batch” | “batch” |

| 30 | 50 | 70 | 100 |

| 55 | 80 | 150 | 250 |

RO/P FURNACES ROTATIVE INCINERATOR

This is a series made up by 6 models of rotating batch combustion chamber furnaces whose movement causes constant removal of the material being treated and as a consequence speeds up the drying and combustion process. The length of treatment and fuel consumption are therefore lower than those in similar static furnaces.

RO/P furnaces

The operating principle of these furnaces is based on slow rotation, constant or batch, of the combustion chamber, which, with the removal of treated material, speeds up the waste drying and combustion process, resulting in shorter treatment cycles and lower fuel consumption than in similar static furnaces.

These furnaces have been designed and developed to solve in a rational and cost-effective way the problems related to the elimination of also large amounts of a wide range of high-water content waste (such as waste from slaughter houses, meat and fish factories, fish markets, fruit markets, etc.) in a relatively low amount of time, at the same time ensuring totally sterile ashes.

Above all if equipped with a “Smokeblock” device to lower water content, this type of furnace is able to fully meet the requirements set forth in Attachment IV of EU regulation no. 1774/2002, and features low consumption and operating costs.

ROP furnaces are delivered in prefabricated elements and are ready to be assembled for easy and safe installation and startup. They do not need to be installed in particular facilities thanks to their small size and compact structure. They can be installed in already built areas or outdoors on a normal cement base with a protective cover. The also feature reduced and simple maintenance.

| Technical Features | Unit of | Model | |||||||||||

| Meas. | 100 | 150 | 250 | 350 | 550 | ||||||||

| Incineration system | = | Rotating Chamber | |||||||||||

| Standard use | = | “by batch” | |||||||||||

| Max. destructive capacity | kg/h | 150 | 180 | 280 | 380 | 630 | |||||||

| Loading capacity | kg/cycle | 200÷300 | 300÷450 | 500÷750 | 700÷1150 | 1100÷1600 | |||||||

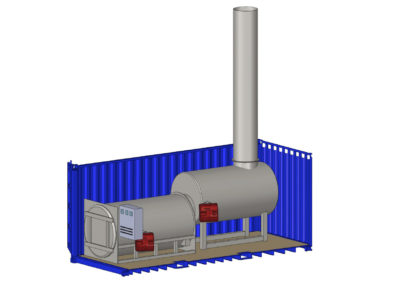

MOBILE INCINERATORS

- CONTAINERIZED INCINERATORS: Ideal for remote locations and doesn’t require housing shed.

- SKID MOUNTED INCINERATORS: Ideal for remote locations that require temporary housing sheds.

- TRAILER MOUNTED INCINERATORS: Ideal for incineration of highly infectious waste at source or point of generation. It minimizes the risk of contamination and re- infection during waste transportation.

- AUTO LOAD / AUTO DE-ASHING INCINERATORS: Mainly used for continuous waste incineration process and fitted on all large waste incinerators. This type of incinerators automatically loads waste and intermittently discharges ash during operation.

HIGH CALORIFIC VALUE INCINERATORS

The plant described below is the result of some recent work that Off. Mecc. CIROLDI S.p.A. has carried out in Italy, United Kingdom, Malta, Russia and middle est.

The plant basically consists of an incinerating line suitable for thermal destruction of industrial waste (but also household or industrial sludge), from 300 up to 3000 Kg/hr (depending on the waste l.c.v.) on a 24 hours a day operation basis and including the following main sections:

– wheeled bin tipper and waste loading system,

– primary combustion chamber,

– transition chamber with automatic ash unloading device

– post-combustion chamber

– heat exchanger unit and dissipater for gas cooling prior to filtration

– flue gas treatment system based on a bag filter, complete with reagents dosing system

– emission parameter monitoring and recording system,